How Goldbacks Are Made

24k Gold is embedded in each Goldback in precise measured amounts of 1/1,000th, 1/200th, 1/100th, 1/40th and 1/20th of a Troy Ounce.

The five individual Goldback denominations (1, 5, 10, 25, and 50) are first designed by Goldback artists, as a Series featuring a State and a set of virtues. This artwork is then combined with government-grade anti-counterfeiting features. After passing multiple reviews, the design is sent to Valaurum, our manufacturing partner here in the US.

24k gold is bombarded onto the polymer under a vacuum.

See video below.

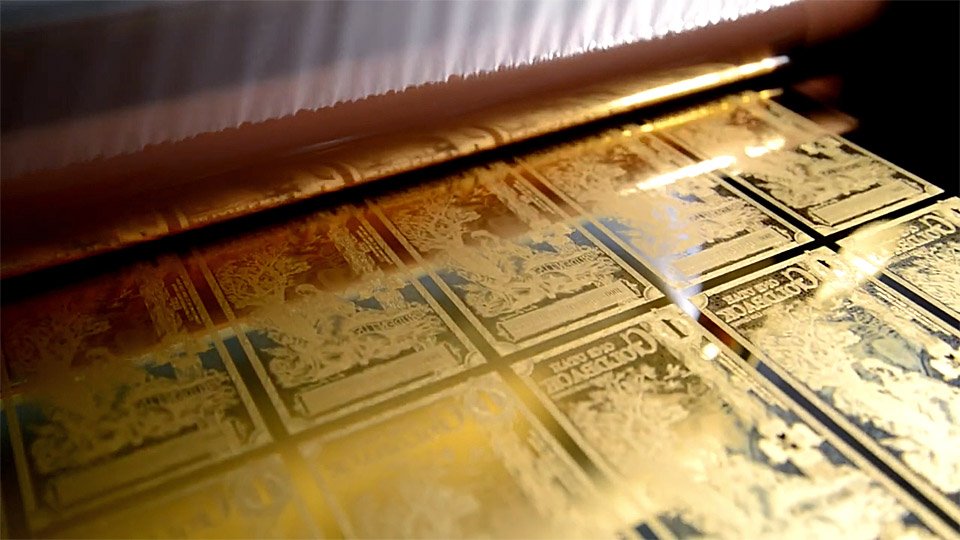

Valaurum then prints the Goldback designs onto 500-foot rolls of polymer sheeting. The 24-karat gold is then vacuum deposited onto the polymer using proprietary 5th-generation vacuum deposition technology. During this step the polymer is bombarded with the precise amount of atomized gold particles.

Nearly complete. The final steps are verification measurements, cutting, and packing.

See video below.

This deposited gold layer is then sealed inside by a second protective barrier of polymer, creating a beautiful negative image on the back side.

Each production run of Goldbacks is precisely verified via . . .

X-ray depth measurement

Fire assay of gold content

Additional third party measurements

Anti-Counterfeiting Measures

Government-grade security

Crystallization and tessellation patterns in each design

Deposited gold retains patterns

Individual serial numbers

Valaurum has been developing the manufacturing process for nearly two decades and it has never been counterfeited.

It is the most technologically advanced process in the world today for creating physical gold that you can spend.

Video — Manufacturing Goldbacks

Video — Are Goldbacks Really Made of Gold?